Moisture in a Refrigeration System

Any amount of moisture or water in a refrigeration system is simply catastrophic and will eventually lead to major failure and extensive cleaning of the system. It is vital that during all stages of the installation, service and repair procedure, that moisture is identified and eliminated from the system. Small amounts of moisture will react with the refrigerant and oil and cause it to become acidic. As this gets pumped around the system, it forms an electrolytic copper coating on all steel surfaces such as the compressor, valves and internal controls. These copper deposits reduce bearing clearances and can cause some components to seize. The acid also reacts with the insulation of the motor windings and can cause electrical burnout of hermetic or semi hermetic compressor motors.

Moisture can also cause the following to occur:

- Sludge that can block oil strainers, reducing oil flow and increasing wear on components.

- It could cause a restriction in the expansion device. This will therefore lower the temperature at the orifice causing the moisture to freeze up and cause a blockage.

- Larger quantities of water will cause a blockage in filter drier cores and can also displace the volume of oil when pumped around the system.

Setup procedure

Setup procedure

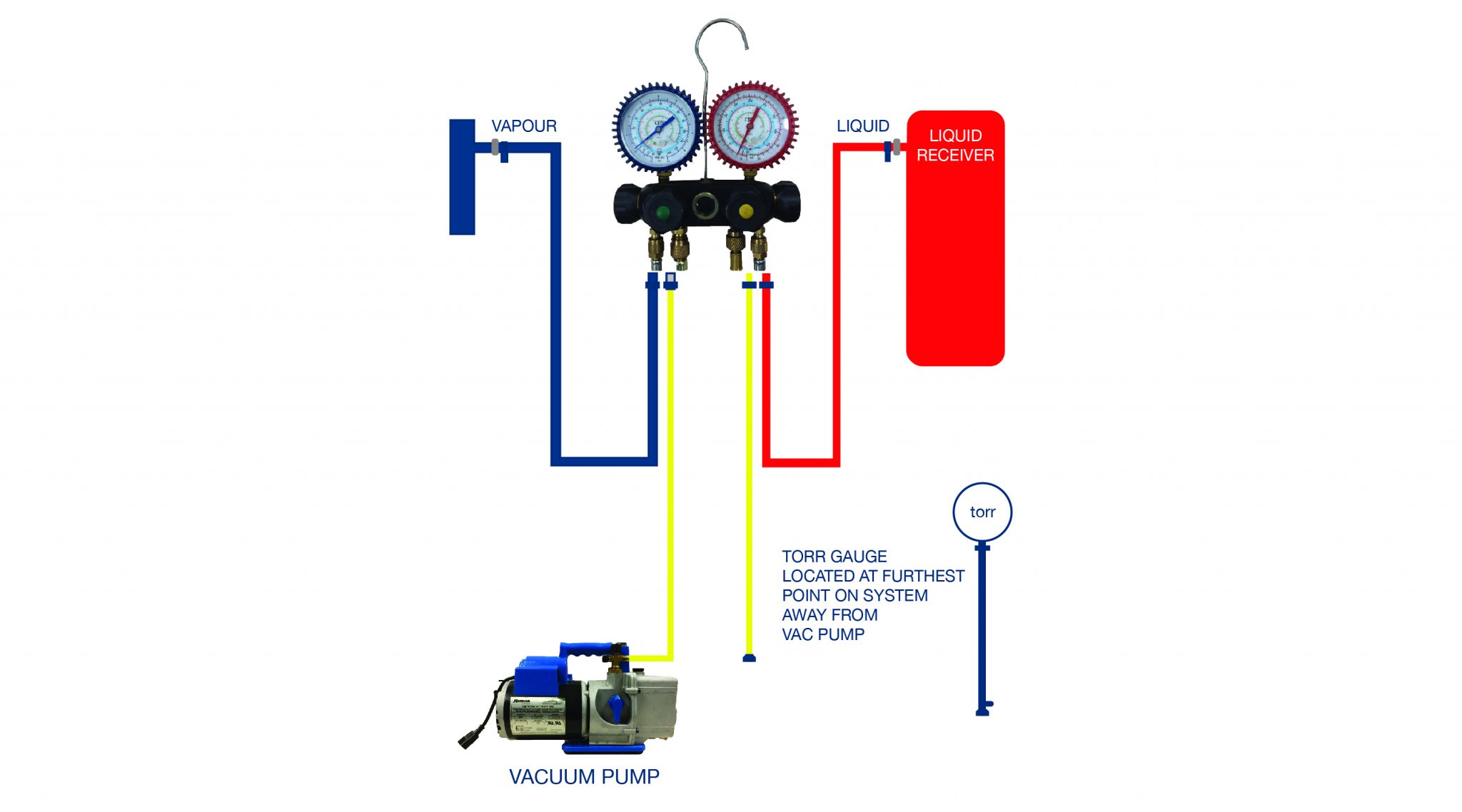

- Connect the lines to both the high and low side of the system.

- Always use a Torr Gauge connected at furthest point away from vacuum pump.

- If manifold gauge hoses are in poor condition, consider using copper lines to connect to the vacuum pump.

Single Vac Method

A deep or single vac is trying to achieve a pressure of 2 Torr in one attempt or a single stage.

The vacuum pump is connected to both the high and low sides of the system and left to run until 2 Torr or below is achieved. Once 2 Torr is reached the pump is isolated and a rise test (negative pressure test) is completed for a minimum of one hour.

Triple Vac Method

The triple vacuum method is mainly used on larger equipment and is the preferred way to remove moisture from the system. After achieving a vacuum of approximately 10Torr, use OFN (Oxygen Free Nitrogen) as a drying agent, to absorb all the moisture out of the air. This method can be used when the ambient temperature is low as it helps to boil off any moisture and speed up the vacuum process.

The sequence for triple vac is:

- System has passed strength/tightness test, OFN vented off in a controlled manner.

- Connect Vacuum pump and gauges to both high and low sides of the system.

- Evacuate system until a pressure of 10 Torr or lower is achieved.

- Isolate vac pump and Torr gauge then use OFN to bring pressure back up to 0 Bar.

- Vac pump is restarted, Torr gauge opened and a pressure of 5 Torr or lower is achieved.

- Vac pump & Torr gauge is isolated and OFN is introduced until 0 Bar is reached again.

- Vac pump is restarted, Torr gauge opened and a pressure of 2 Torr is achieved.

To ensure that the system is free of leaks the pressure must be maintained without significant rise for at least one hour with the vacuum pump isolated.

Note: During any type of vacuum procedure make sure that all valves & solenoids are open. This will ensure that no ‘pockets’ of air or nitrogen are trapped in the pipe work. If a component is closed or restricted then connect a hose to both sides of the component.

FOR MORE INFORMATION ABOUT REPAIRING REFRIGERATION SYSTEMS PLEASE JOIN OUR FACEBOOK GROUP